The scope of Autel's electronic control devices is sufficient for both small sized and large scaled companies to meet their needs.Autel produces timer models with 3 different cycles.STR-REC model which is economic and compact one , GC model which is economic cyclic generator and TC model with single output.Reliable STR-REC model is compact and the number of output is minimum 2 and maximum 6 but it is able to be increased by expanding REC( Remote Expansion Control).In this case it can be used for both small sized and large scaled companies GC products which are cyclic generators are designed for constant and serial control and enable to organise stopping and restarting times at regular intervals.This device can be obtained with different models that can control minimum 2 maximum 96 electrovalves and therefore these devices can be used in both small sized and large scaled companies.Autel can provide very large scaled companies with the timers which can control more than 96 electrovalves with necessary expansions on the device in case of requirement.TC cyclic generator is very simple and reliable timer with a single output and these devices are designed for direct installation on the valve to be used.

As DTI :

We advise filtration plants to use ''MAINTAINER'' designed to make smart control because this device economizes energy consumption in the air filtration operation .MAINTAINER can command electrovalves and has got differential pressure measuring instrument.MAINTAINER enables to control the congestion degree of the filter directly and to work cleaning system only when needed and in the right location.This smart device can recognize the outputs loaded and therefore control only the outputs used actively otomatic and directly.MAINTAINER can be obtained with different models that can control minimum 2 maximum 96 electrovalves so they can be used in both small sized and large scaled plants. In case of requirement MAINTAINER expansion moduls can be used to guarantee to control more than 96 electrovalves and thus this device can be used in bigger plants.

SOME SIMPLICITIES THE MAINTAINER PROVİDES |

|---|

- Minimum and Maximum pressure alerts

- Alerts of ''Shaking Active''/''Shaking Finished''

- Alerts of valve error

- The indicator of automatic pause

- The indicator of input active

- The external shaking

- Remote start and stop

- Activating remote automatic and manual shaking mode

- Alerts of '' System OK''/''System ON''

- Alerts of detecting ''Torn Bag'' and ''Flat Bag''

- Indicators of ''valve working'' and ''valve pausing''

- The indicator of automatic cleaning mode

- The alarm of external pressure key

Input tribo (used for detecting flat/torn bag) - Activating remote automatic pause and shaking mode

- The pressure control of the tanks

MAINTAINER TECHNICAL SPECIFICATIONS |

|---|

| Protection degree | IP56 | Post Cleaning Time | 0-999 sn. Precision: 0,01 sn. |

|---|

| Power Source | 24 WAC, 45-60 Hz veya 115 WAC, 45-60 Hz veya 230 WAC, 45-60 Hz 24 WDC Vdc power source can be obtained if required | Outputs | Zero pass (activation/deactivation triac) side conductor device 24, 115 or 230 Vac maksimum

Current: 2A 24 Vdc Transistor type for the versions designed to control selenoid valves (optional) |

|---|

| Power absorbency | 30 VA | Alarm Relay Outputs | 1A resistance load 115 Vac |

|---|

| Fuse | F1 , F2¹ = 2A 5X20 fast moving | Clock counter interval | 0-99999 hour |

|---|

| Working temperature | -10/+50 ºC | Cycle counter interval | 0-99999 cycle |

|---|

| Connection | Screw terminal panel | Nominal measuring range | from -99 to 9999 mmH2O |

|---|

| Pause Time | 1-999 sn. Precision: 0,01 sn. | Accuracy | +/- %1 F.S., +/- 1 step |

|---|

| Working Time | 0.03-9.99 sn. Precision: 0,01 sn. | Maksimum applicable pressure | 0,5 bar |

|---|

INSTRUCTIONS |

|---|

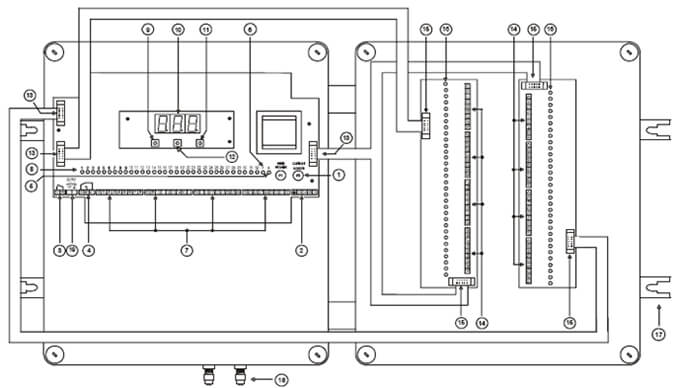

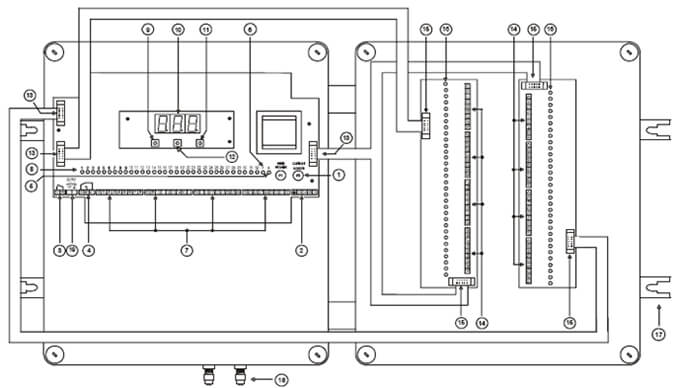

| 1 | F1 main fuse / F2 load protection fuse | 11 | Increasing Key ( ↑ ) |

|---|

| 2 | Power source terminal panel | 12 | Enter key ( E ) |

|---|

| 3 | Post cleaning input from distant contactor ( on= after cleaning off= stopping) | 13 | Connectors for linking economizer to expansion boar |

|---|

| 4 | Alarm output (relay change point) | 14 | Terminal panel for connection of selenoid valves in expansion board |

|---|

| 5 | Power ON light | 15 | Connectors for linking expansion board to economizer |

|---|

| 6 | Pause light | 16 | Expansion board output active/passive light |

|---|

| 7 | Controller connection terminal panel | 17 | Fixing prop |

|---|

| 8 | Output active light | 18 | Pneumatic connection unit |

|---|

| 9 | Reducing Key ↓ ) | 19 | 4-20 mA output (optional)) |

|---|

| 10 | Screen with 3 steps | | |

|---|